Roller Conveyor Selection Guide

Roller Conveyors

Our gravity roller conveyors can transport light, medium, and heavy duty loads that gave firm flat bottoms such as cartons, totes, cases, skids, drums, etc. Ashland's line of roller conveyors includes models with the roller from 1-3/8" to 2-5/8" diameter and various frame styles. Our roller conveyor sections come in 5' and 10' lengths as well as 45 and 90 degree curves. Some models can be installed permanently or used for temporary set-ups. Although we cannot meet every roller and frame combinations, take a look through this guide to learn how to choose the right roller conveyor for your application.

Roller Conveyor Model Summary

We have many combinations of frames and rollers that are described by their short description. Refer to the model below to see how we abbreviate our roller conveyors.

Choosing Your Conveyor

The best place to start when choosing a roller conveyor is to determine the weight and dimensions of the product you wish to convey. This will narrow down the roller, frame, width, and roller centers that you will need for your conveyor. Once you determine the conveyor model needed for your application, you can filter through our roller conveyor section here.

Between Frame Dimension

At Ashland Conveyor we measure all of our rollers and roller conveyors by the between frame dimension. The width of your product will determine the between frame dimension. It is recommended to use a conveyor that leaves 2" of roller on each side of the product to ensure the product moves smoothly.

Are you trying to match an existing conveyor system? Measure from the inside of one rail to the inside of the other rail where the rollers sit. This will give you the between frame dimension of your roller.

Frame Capacity, Style, and Couplings

We have different frame styles that can provide different options for your application. Ultimately the frame style will be determined by the capacity requirements of your application. Options include material, frame height, shaft holes, roller position, construction, and capacity.

The frame must be capable of supporting both the conveyed items in addition to the frame and rollers. Each roller conveyor will have the capacities listed in the construction. These capacities are based on 10' support centers and 5' support centers. Having supports located every 5' will increase the frame capacity, whereas having supports every 10' will decrease the frame capacity.

All of our conveyors are equipped with couplers. These are used to connect multiple conveyor units together to form a run and give stability to the system. The conveyors will either have Hook and Rod couplers (HR) or Butt Plate couples (BP) The coupler style will be noted at the end of the conveyor short description. All couplers are bolted or welded into the frame depending on the frame model.

Curves

Often curves will determine the width of the conveyor system, as the product requires additional space to negotiate the turn. The additional space depends upon the length and width of the product. Take a look at this link from our catalog for information on choosing the correct between frame dimension.

Roller Centers and Roller Position

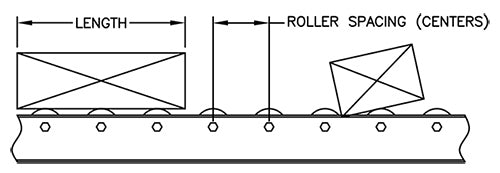

A minimum of three rollers should be in contact with the load at all times. Roller centers man also need to be closer together to reduce the load per roller. If you are moving a light and longer product, you can increase the roller centers to reduce the weight and cost of the roller conveyor.

Looking to match the roller centers of an existing conveyor? Measure the distance between the center of one roller axle/shaft to the next roller shaft. Depending on the model of conveyor, our roller centers are 1.5", 3", 4.5", and 6" centers.

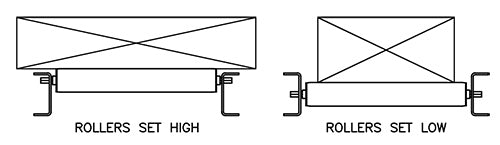

As a standard, all of our rollers will be set high in their frame. This will allow for some overhand of product if needed for your application. If you need to make sure your products will not slide off the sides of the conveyor, you can attach guards to your frames. You can also purchase our conveyors with the rollers set low in the frames. This option is not available on our website and will have an additional cost and lead time. You can make this request through a sales representative.

Supports

Our conveyors do not come with the supports. Supports come in different styles and heights. It is possible to use our conveyors without supports and lay them directly on a flat, even surface. When pairing your conveyor with supports, you will need to match the between frame dimensions (except for tripod and low profile supports). To learn how to select the correct supports for your conveyor click here.

Accessories

Our conveyors are compatible with many accessories that can tailor your application to your needs. Not all accessories will work with your conveyor. Make sure to read the product descriptions to see which conveyor model each accessory will work for. To see a list of accessories that we can supply, click here.